My dad came down today, and we got a lot done.

2.5 of the 3 lower manifolds are now complete, and the fountain plumbing is now good enough for the pool rebar to be installed. This is great news because it means I am nearly released from the critical path and we can go from having one amateur working two days a week to maybe three or four professionals working 5 days a week. I expect a speedup of at least 7 times!

The bottom manifolds are made of flexible PVC pipe. This stuff is made with two different plastic formulations coextruded. The first is rigid white PVC, just like regular pipes are made of, which is formed into a spiral. The seconds is flexible PVC (with Phthalate mixed in for flexibility), which fills the gaps between the coils. This stuff is a little tricky to work with.

The first problem is that the pipe arrives in coils. By the time you get it, the stuff has achieved something of a permanent bend. I was able to take most of this out by unwinding the stuff down the middle of the pool, where it got hot in the sun for a week.

I have not determined a good way to cut the flexPVC. I'm using my miter saw to cut my pipe, because it makes such nice clear burr-free cuts on the regular PVC pipe. On the flexible stuff it leaves a hot, smoking cut with lots of burrs that I clean up with a knife. The Phthalate is particularly annoying, because our chickens love to eat the PVC chips from the saw, and we eat the chicken eggs, and phthalate is bad stuff. So, the chickens are cooped up on days when I'm cutting flexPVC, and I vacuum up everything afterwards.

We're also having difficulty just measuring the stuff. Somehow we're making lot of mistakes where we measure, cut, and then find that it's not the right length. I think the basic issue is that we're trying to measure curved paths with a tape measure.

Joints are a little scary with the flexPVC pipe. I had a professional plumber recommend that we encase every flexible PVC pipe joint in concrete. Now that I've done a bunch, I agree. If there is any bending load on the joint when it's made, the pipe sits in the socket at an angle, and in a few of those joints I can feel that the PVC glue has not completely filled the space between pipe and socket. I made most of the joints with no load while it was curing, and let them sit for at least a day before putting load on them. Those joints I'm quite comfortable with.

Dad points out that if I have a few leakers, the leak rate will be very low due to the concrete barrier and very low pressure in the system (3-6 psi). The plan is to pressure test before gunite, but that is going to be hard to pull off. I'm concerned I'm going to have leaks in the plastic membrane which collects the water, and this will hide any leaks in the piping.

Sunday, March 29, 2009

Wednesday, March 25, 2009

Quick post: Credit Crisis Explained

Great 10 minute animation explaining the credit crisis:

http://vimeo.com/3261363

http://vimeo.com/3261363

Sunday, March 22, 2009

Zubrin's Plan

Energy plans are like ..., well, everybody's got one. Today I'll be looking at Zubrin's plan, as presented by Anne Korin. Check out her youtube presentation.

Anne likes Robert Zubrin's plan of making lots of ethanol from corn or sugar, and using that instead of oil to run our cars. Digging below the surface, the bottom line is that in 2008 we used 42% of our corn crop to reduce oil imports by 3.7%. So, we aren't going to replace a substantial amount of oil imports this way. But Anne didn't get into that aspect.

Anne's politics are certainly different than mine. She likes to talk about having little or no government, and letting the free market work. At the same time, the present crisis is so very bad, and OPEC is removing freedom from the oil market, so she says we need the government to fix it. Okay, so she's libertarian except when things are bad. A governing system that only works in good cases doesn't sound very robust to me, but that's not really the point of this blog post.

Another issue I have with her otherwise excellent presentation is that I don't follow how OPEC, which controls about half of the oil supply, can remove freedom from the market. You can read a detailed analysis at WTRG Economics which suggests that OPEC does not have even rough pricing control.

But I think this is just her ideology, and I don't care about that so much. What is more interesting is her presentation of Zubrin's plan (unattributed) for fixing our balance of trade / economic insecurity problem.

The basic idea in the Zubrin plan is to mandate that all cars sold in the US accept both alcohol and gasoline fuels. This change can be applied to all cars sold within a couple of years because it does not require large changes by auto manufacturers (contrast with hybrids, or plug-in hybrids, which have a much longer and more expensive adoption curve). Having made that change, within a few years a substantial number of consumers will be able to use high-alcohol-content fuels.. When alcohol is cheaper than gas, gas stations will offer alcohol, and so consumers will have an economic alternative to gasoline.

We can make alcohol from corn or coal, or we can import alcohol fuel. There are a lot of hazy details: corn-ethanol may be soaking up so much corn that we're starving people to death worldwide, corn may be crowding out the use of land for food, and it may be impossible to grow enough corn to matter.

The flex-fuel vehicle part sounds really good. There are a few other details which sound really good to me as well:

- Eliminate the tax on imported ethanol, so that it competes with imported oil (which has no tax).

- Eliminate the tax on imported sugar. Sugar cane is supposed to be a better feedstock for ethanol production than corn.

In the presentation above, one of the audience members asks if ethanol from corn replaces more oil than it consumes. Anne says yes, and it appears she is right. Here's a study of corn-ethanol production efficiency:

- Each BTU of corn-ethanol produced in the U.S. requires an average of 0.14 BTU of gasoline, diesel and fuel oil.

- This factor does not support the conclusion at the top of the study, that each gallon of ethanol displaces 7 gallons of imported oil.

- Correcting for the energy density of ethanol and gasoline, each gallon of ethanol produced domestically displaces 0.57 gallons of imported gasoline.

- The U.S. produced 13 billion gallons of ethanol in 2008, which displaced 7.36 billion gallons of gasoline, and reduced oil imports by 167 million barrels. We imported 4.39 billion barrels over the same period, so the oil imports reduction was 3.7%.

- The U.S. used 5.1 billion bushels of corn in 2008 to make that ethanol, which was 42% of the total of 12.3 billion bushels grown that year.

Bottom line: we aren't going to displace more than, say, 10% of our oil imports in the future by using corn ethanol. There just isn't enough corn.

The reason the question gets asked is that there is a different issue: does making corn ethanol yield more fuel energy than fossil fuel energy used? The answer here is: it's close. When you make ethanol, you make electricity along with it. When you add in the energy value of the coproducts, a little more energy comes out than fossil fuel energy went in (this energy was supplied by the sun).

So, the right way to think of ethanol production is as a coal-to-liquids system. It has the consequence of increasing the total amount of carbon dioxide emitted for a given amount of energy delivered to the automobile.

Thursday, March 19, 2009

Fountain Progress

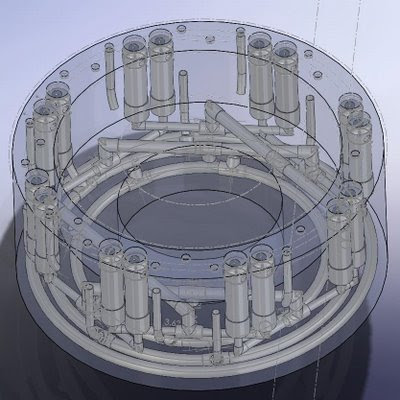

The guys at work are calling it my nuclear reactor.

Thanks, Ryan and Wes!

Monday, March 16, 2009

Sanctity of Contracts

Over the last few years, AIG sold insurance against defaults on mortgage back securities. They sold huge amounts of this insurance, at low prices. Those insurance contracts call for AIG to post bonds which show the ability for AIG to pay, should it's credit rating drop.

Now, because it is supposedly in the U.S. taxpayer's interest that the folks who bought this insurance not suffer any loss, our bailout money is being used to post those bonds. Furthermore, the people at AIG who misestimated the likelihood of defaults on mortgages, and thus mispriced the insurance, are being paid huge bonuses, again with my money.

AIG's position is that both the bonds and the bonuses are required to be paid by contracts that AIG signed. Those contracts cannot be abrogated.

Complete crap. Those contracts can't be abrogated by AIG. There is no such contractual obligation on the U.S. government. AIG is failing. If we let it fail, part of the bankruptcy proceedings will be that some entity, possibly the government, will purchase some portion of the assets. They make take on some of the liabilities if they so choose, as well. So, during the bankruptcy proceeding, the government can negotiate with the folks who have claims on AIG's assets to determine what percentage, if any, of those liabilities the government chooses to fulfill.

Since every serious person involved understands this already, the government can renegotiate those credit default swaps even without AIG going bankrupt. This is called a workout, and it happens between creditors and debtors all the time. If the debtors don't like the proposed workout, they can force the company into bankruptcy.

As part of this workout, we can reduce the bonuses to the folks that sold the credit default swaps to zero. If this causes them to be unable to afford their current homes, that is karmic justice. My guess is that if outraged AIG salespeople attempt to recover a portion of their bonuses by forcing AIG into bankruptcy, they'll be either shot down by a reasonable judge, or just lynched.

Wednesday, February 25, 2009

Fountain Basics

This post is a response to Jim. Jim has several 0.125" diameter hoses that he cut with a clean edge, and supplied with pressure from a garden hose. His fountains shoot up to their apex, then break up into a gloppy mess, just like mine used to, but for a different reason.

There are three, well, no, six things you need to make a laminar stream work:

- Accelerate the water to high speed without producing a lower-speed boundary layer. After the water exits the nozzle, internal shear will accelerate the boundary layer back up to the speed of the jet, and the shear will then be redistributed through the jet as turbulence, which will then lead to breakup. I know of two ways to minimize the boundary layer:

- Large diameter tube ending in a flat plate with a small diameter hole. This design minimizes the distance over which the water is both at high speed and in contact with the wall. There will be a boundary layer, but it'll be really thin. The downside is that you end up with plumbing behind the jet which is really bulky compared to the jet.

- Form the jet first, then use a circular knife to cut the boundary layer off the main flow before the boundary re-accelerates. This is how firehose nozzles work. They take the water stripped off and reintroduce it to the stream with a venturi. This nozzle is less bulky but needs a bigger pressure drop and is more difficult to make.

- I found that water beads up on my 316 stainless nozzle more than on my PVC pipe. It's possible that the 316 doesn't drag on the water quite as much as PVC would have, although I can't confirm that.

- Remove all vorticity from the water.

- The problem is that angular momentum is conserved, and angular momentum is (mass)*(tangential velocity)*(radius). When you constrict a flow from 6" diameter to 0.5" diameter, the velocity increases by a factor of 12x, which means the centripetal force increases by 12^3 = 1728x (that's right, v^2/r). If my 6 inch flow starts out at 3 RPM (20 seconds to turn once, barely turning), then the half-inch jet will be rotating at an average of 432 RPM, and the centripetal force at the surface will be 13 m/s^2, which is more than 1 G. Since 1 G will rip drops of water off the underside of a wet object when the water is much less than a half inch thick, it's no surprise that this rotation will rip apart a half-inch diameter stream.

- A long, narrow nozzle should take out vorticity through friction with the nozzle walls. The same friction will lead to lots of turbulence. I have no idea why this turbulence is not a problem for the firehose nozzle. I did some experiments with a watering can that we have which features a nozzle about 12" long and 1/3" diameter, and found that the stream would travel about 3 feet before it broke up.

- If you do the large-diameter, hole-with-flat-plate nozzle, then you have to remove the vorticity some other way. I did it with layers of twin-wall polycarbonate, cut on a table saw, epoxied into place. In this YouTube video, they do it with soda straws. I've read that the minimum length needs to be 12x diameter. My flow straighteners are 1 foot long, and have channels 7mm across, so the ratio is 43:1. Probably overkill.

- Eliminate even minute variations in your water flow.

- You'd think a hose bib would give you smooth water flow, but it doesn't. I know because my fountains shot blobs of water with direct pressure from a hose bib, but worked fine once I put an LC filter between the hose and the fountain. The YouTube video mentions the same problem in passing, but doesn't say how to fix it. Directly connecting my pump led to blobs, the LC fixed them too. (My hose bib has 200 feet of 1/2" copper pipe leading to it, so I'm astonished that any flow variations were getting through. My best explanation is that the copper pipe is elastic, and the resulting distributed capacitance combined with the pipe inductance is forming a transmission line.)

- The filter is simple: you have a run of smallish diameter pipe (that's your inductor, 20 feet of 4x your jet diameter should do), and a Tee fitting going to a vertical pipe into which the water can expand momentarily (your capacitor). My expansion pipe rises higher than my fountain jets, and is open to the air, so that it acts as a pressure regulator as well. I found that the water from my pump in my 2" PVC pipe would flutter irregularly perhaps 1/4" up and down. You can also do it with a closed pipe that traps air above it, if you can figure out how to ensure there is air up there. So long as you don't introduce bubbles into the stream, the closed pipe should work better because it has a smaller column of water between the pressure source (air) and the flow. That column acts like an inductor which would tend to isolate the capacitor and limit its high-frequency response.

- If the source of variation is turbulence in the fountain, then you'd want the capacitor close to the fountain, and the inductor between that and the supply (hose). If the source of variation is the supply, then you'd want the capacitor at the supply, followed by the inductor going to the fountain. When filtering power into sensitive analog electronics, we use "pi" networks, which are just a capacitor at both ends of an inductor, basically because the noise could be coming from both places and we are hedging our bets.

- Get rid of all air bubbles. Even tiny bubbles cause major flow disruptions. I have my pumps below grade, so that the water pressure at their intakes should be either above air pressure or very close to it. This should eliminate air leaks past the O ring on the strainer basket cover, which I think was a source of bubbles in my last pool. The strainer baskets always seem to have a little air pocket at the top.

- Don't go straight up. I may have screwed this one up. My jet angle is just 12 degrees off vertical (here are my calculations), so that the jets slow from 19.7 feet/second at the nozzle to 4.1 feet/second at the apex. The extra flight time and variation in velocity give the flow more opportunity to glob up.

- Filter the water. I may have screwed this one up as well. I wanted to have low power pumps (700 watts total) push a lot of water (200 gallons/minute), which means very low pressure head (10 feet or 4.3 psi). No filter that I know how to buy has ports larger than 2 inches, so any standard filter would have a very high pressure drop. So instead I have 7mm holes in my flow straightener, and .590" holes for my nozzles, and I'm hoping to catch anything even nearly that size in the strainer baskets of the pumps. I also have the ability to backwash my flow straighteners using filtered water from the main pool pump, which can crank up to 3.5 horsepower if needed.

Okay, so Jim, here's your problem: those presumably short hose segments are making a big boundary layer in your jet, so when it slows down near the apex there is plenty of time and turbulence to glob up. The problem is worse because the jets are just 1/8" diameter, so the boundary layer may be the entire diameter of the jet. You need to pick a different, bigger nozzle. I can recommend the flat plate nozzle, and the YouTube video above shows you how to do it cheaply. You are also going to need to smooth out the water supply from the hose, and the LC filter described above should do that at low cost.

Good luck, and please let me know how it goes! If you can, post pictures of the flow at 1/1000 second exposure or faster (full sunlight with any camera will work great).

Other links:

- Pretty good Google Answer on the subject

- Badly formatted webpage, no pictures, but same idea here. They actually worked on chopping the stream on and off.

Monday, February 09, 2009

Wider blog posts

I have no idea why the standard blogger entries are so skinny. Maybe they want to be compatible with cell phone users.

I got fed up with the skinniness, and expanded the format using the instructions provided here. Thanks, IDS.

I got fed up with the skinniness, and expanded the format using the instructions provided here. Thanks, IDS.

-Iain

Fountain update

Monday, January 19, 2009

Fountains, fixed

Much happier. I now have two unit fountains, operating in parallel, driven from a pump, with a filter that takes out most pressure variations. There is some unsteady flow remaining, which I think is due to bubbles. I have good reason to believe there will not be bubbles in the production pump system for my fountain, so I think the design is now validated.

As a side effect, everyone involved with the testing is now soaking wet. Much of the piping is not actually solvent-welded together right now, so there were the occasional blowouts. Fortunately, we have a blue sky and 75 degree air outside right now, so wet is just fine. If we had a pool, we'd be swimming (ahem).

Here are two unit fountains running at about 60% of design flow. Note the smooth flow. It's splashing a bit when it hits the tub, but that'll go away when it's got more than a half-inch of water to fall into.

Details:

- The streams do not quite reach the same height. I'm pretty sure this has to do with a small difference in their pointing angle, so I'm pretty sure they'll all line up when properly installed dead vertical.

- When supplying the fountains with water from the hose, pressure variations from the street supply were making their way to the fountain. These were probably low-frequency variations, maybe 1 to 3 hertz.

- I considered a surge tank, but the volume required was too large (over 20 gallons). Instead, I have a simple open-topped vertical pipe teed into the line from the pump to the fountain. The pipe only needs to be a few inches taller than the height of the fountain jets. The production system will have perhaps an extra foot or two. You can see the pipe in the foreground.

- I tried placing the tee close to the unit fountain, and that worked well, and then I tried placing it next to the pump, and that worked about as well. This result indicates the flow instability comes from the pump and street supply, and not from turbulence within the fountain itself. (Whew!)

- The nozzle is a nonlinear resistor, so it was moving the energy from low frequency variations to higher frequency harmonics.

- The nozzle is nonlinear because it converts pressure into velocity head with almost perfect efficiency. If you double the pressure, you double the velocity head -- the height to which the water will jump. I confirmed this by varying the flow through the system and noting that the water always jumped to a few inches lower than the water level in the vertical pipe capacitor. A doubling of velocity head means an increase by sqrt(2) of velocity, and flow is (sort-of) proportional to velocity. As a result, flow increases with the square root of pressure.

- The nozzle diameter is 0.500 inches, but the flow diameter appears to be 0.410 inches. I didn't expect this. The reason is that the flow at the knife edge is horizontal, and it turns through a radius of 0.045 inches. I suspect that at the higher flow velocity in the production system, the stream diameter will actually decrease.

- As a result of the small stream diameter, I'm going to have to throttle back the pumps. The fountain was designed to throw 193 gallons per minute 59 inches horizontally with 16 0.500" diameter streams. Now that the streams are smaller, I'll have to throttle back to 130 gallons per minute, or lower. I'm not too happy about that.

- The stream is even more wickedly nonlinear than the nozzle. The principle problem is that slightly faster flow has over a second to catch up to slightly slower flow. The stream goes at about 140 inches/second at the nozzle. So a 1% variation in flow yields a longitudinal variation of over 2 inches by the time impact happens. If that happens in less than 10 inches (more than 14 hertz), you get blobs large enough to cause the stream to turn into drops.

Sunday, January 11, 2009

Fountain Ballistics

There is a common thread among the questions I get at parties:

"How's the fountain coming?"

"Any news on the fountain?"

"Any progress on the fountain?"

or, from Martha, "Are we ready to can this turkey?" Sometimes at parties!

As a public service, I thought I'd post how things are going.

First, you should understand that the pool will have an 8' diameter round hot tub stuck into the otherwise straight side. 16 streams of water will issue from jets embedded in the wall of that hot tub, and land in a small circle in the center. There is a lot of plumbing to make this work, and here is a partial CAD model of it all:

Each of those fat vertical things is a unit fountain, and each contains a diffuser and a flow straightener, and is topped with a head with a nozzle embedded in it.

I've machined the diffusers, cut some flow straighteners, machined the nozzles and heads, and assembled a single unit fountain. I didn't glue it together. I supplied it with water from a hose.

Here's how I machined the head. I started with a 6" PVC end cap, and milled a flat on the end and two shoulders on either side. These are for aligning the side ports to the nozzle later. You'll see.

Then I put it on a Bridgeport mill. Below, you can see that the quill of the machine has been canted 12 degrees over from vertical. This makes the angle that the water jet will come out on, so that it launches from the wall of the hot tub and lands in the hot tub. You can also see the parallel on the two studs in front, which fits against the shoulder I cut earlier. This edge is parallel to the X axis of the mill. So the mill is canted 12 degrees in the plane of this shoulder, which means I can drill holes in the end cap aligned to this nozzle later.

Here's me working the thing. It turns out that lubricant makes everything a lot easier. The Forstner bit was not the best thing to cut this hole with, as I got a lot of heating and chatter. Occasionally the mill would throw chunks of plastic across the room, so the safety glasses were a must.

I cut the diffuser on a ShopBot at the Sawdust Shop, out of 1/4" PVC sheet. The ShopBot is a CNC router. You program the computer to move the router (they call it a spindle because it goes up to 25000 RPM) in 3 axes. Programming isn't too hard -- you use a ShopBot program to convert line drawings (AutoCAD type, I made them in SolidWorks) into tool paths. We wrote some text programs to step and repeat the pattern once we had it properly tweaked.

The table is covered in chips because we didn't run the vacuum. The owner didn't want to mix PVC chips into his sawdust since he uses the sawdust for something.

Result: just after the hose is turned on, it works great. Flow is smooth almost all the way to the end, certainly good enough to be acceptable. Here it is just after startup. Understand that the unit you are looking at will be one of 16 buried in the wall of the hot tub, and the streams will issue from holes cut into the sides of the tiles that cover the top of that wall. So you won't be looking at ugly PVC.

However, within a matter of seconds, the flow becomes less smooth, breaks up, and soon I have a gloppy mess at the impact point.

Another (minor) problem: I've got a small leak between the nozzle and the endcap, right where the shoulder is thinnest because I've got the flat spot. This is eventually going to be buried in concrete, which will greatly slow the already trivial leakage, but I'm not thrilled about this either. This problem I probably won't fix.

My guess is that I'm getting variations in the flow rate. The fountain is extremely sensitive to these variations -- a 1% change in flow (from 193 to 194.98 gallons/minute) makes a 2.1% change in vertical height and a 2.0% change in horizontal throw. 2% doesn't seem like so much but it's over an inch, for a stream which is around a half-inch in diameter. I think the variations I was seeing were at least an inch of throw, at frequencies from 3 to 10 hertz.

There are two possible reasons I wasn't seeing the variations at first:

- Because the hose wasn't fully up to pressure. The hose is not linearly elastic. When I first turn the water on, the hose fills with water, but it doesn't develop any pressure until it sees back pressure from the nozzle. At partial flow through the nozzle, the back pressure is low enough that the hose is quite stretchy, and so it acts as a surge tank and filters flow variations. At full back-pressure (probably just 2-3 psi), the hose has developed it's fully round shape and is considerably stiffer, losing the filter function.

- If there is air in the fountain, it will act as a surge filter. If I could figure out a way to insert a tennis-ball-sized flaccid bladder filled with air into the fountain, I'd probably have this problem licked, but I'd need something guaranteed not to leak in 30 years immersion. I don't know what that is.

Obviously I need to figure out exactly what is going on, and how to fix it. I'll post some analysis later.

Wednesday, January 07, 2009

Tooth Fairy Traffic

Anya just had a tooth pulled by the dentist. She put it under her pillow but the Tooth Fairy seems to have not made it last night. A few notes:

- The Tooth Fairy came on the fourth night after she lost her last tooth. Anya's theory is that the day before she lost that tooth, a little boy lost one of his, but he was sick, and the Tooth Fairy caught a bug when she touched the tooth.

- I believe Anya is lying, eyes closed, in tense anticipation of the Tooth Fairy. She was watching Martha and I as we climbed the stairs last night at 1:30AM, and she was wide awake and ready to go at 7:00AM when I got her up this morning.

- Little girls, of which I have 3, have 20 baby teeth each. Even discounting the molars, which might come out much later, I can forsee a time when the Tooth Fairy will be making more than one visit per month. With multiple little girls engaging in outright deceit in their attempts to catch the poor fairy, I forsee delays and uncertainty.

I'm not sure if the full-body tension I'm feeling right now is because I'm worried that my contractor won't be able to lay out my circuit board properly, or because the damn house creaks even though it's only six years old. Yeesh!

Thursday, January 01, 2009

5 Ways to Die During Reentry

If you haven't already seen it, the Columbia Crew Survival Investigation Report.

But then the cabin blew apart and they were in their suits in a mach 15 airstream. I didn't actually read this anywhere, but it sounds like most of the suits came off before they hit the ground.

During reentry, there is a 10 minute long window of maximum heating. They almost made it through all 10 minutes. Right at the end they lost their hydraulics. Makes me wonder if they could have flown the orbiter at a funny incoming angle to spare the load on the left wing. Maybe they wouldn't have gotten Columbia onto the ground, but if it had broken up five minutes later things might have gone a bit better.

There were 40 seconds after loss of control during which the Columbia pitched up into something like a flat spin, and the folks inside tried to get their hydraulic systems back.

After that, they had a depressurization that took less than 17 seconds and probably, hopefully knocked everyone unconscious. Nobody dropped their visors (which would let their suits handle pressurization). Apparently they were all in "fix the vehicle" mode and not in "survival as long as possible" mode.

After that the cabin seperated from the rest of the vehicle, the crew's shoulder and other restraints mostly didn't work, and they got thrashed to death: fatal trauma to their heads from the insides of their helmets. Owww.

From my reading, had they dropped their visors, gone to suit oxygen, and braced, several of the crew could have made it through both depressurization and cabin separation.

But then the cabin blew apart and they were in their suits in a mach 15 airstream. I didn't actually read this anywhere, but it sounds like most of the suits came off before they hit the ground.

Side note for camera geeks: notice how crappy the home video shots of the breakup look. Then look at the Apache Helicopter shots of the same thing, especially when it zooms in. That chopper has some nice telescopes!

Monday, December 29, 2008

"we want these detainees broken"

From "SENATE ARMED SERVICES COMMITTEE INQUIRY INTO THE TREATMENT OF DETAINEES IN U.S. CUSTODY":

- Former Navy General Counsel Alberto Mora: “there are serving U.S. flag-rank officers who maintain that the first and second identifiable causes of U.S. combat deaths in Iraq – as judged by their effectiveness in recruiting insurgent fighters into combat – are, respectively the symbols of Abu Ghraib and Guantanamo."

- Jonathan Fredman, chief counsel to the CIA’s CounterTerrorist Center: "If the detainee dies you’re doing it wrong."

- In mid-August 2003, an email from staff at Combined Joint Task Force 7 headquarters in Iraq requested that subordinate units provide input for a “wish list” of interrogation techniques, stated that “the gloves are coming off,” and said “we want these detainees broken.”

- JPRA Commander Colonel Randy Moulton’s authorization of SERE instructors, who had no experience in detainee interrogations, to actively participate in Task Force interrogations using SERE resistance training techniques was a serious failure in judgment.

- Secretary of Defense Donald Rumsfeld’s authorization of aggressive interrogation techniques for use at Guantanamo Bay was a direct cause of detainee abuse there.

I think at this point I'm just sick of all the damage that has been done to my country by Bush and his team. I doubt that throwing many of them in jail will do much to improve the behavior of similarly-minded people, but I'm all for prosecutions so long as they don't shift attention from the job at hand, which is to fix the economy.

Thursday, December 18, 2008

Insulating the pool

Since this is my first posting about the pool, let me show you around a bit. South is to the left. You can see all along the south side of the pool there is a two-foot-wide shelf. The water over that shelf will be 12 inches deep in the shallow end and 18 inches deep in the deep end. In the middle of the south side you can see where the hot tub will go. At the far end (west), you can see the shelf that will eventually support the automatic cover vault. To the left of the pool, at the far end, you can see the pump vault that will hold the pumps below ground, behind baffles, which should make them completely silent. The top of the wooden form will be about three inches below the coping around the pool, so you can see that the coping is about 18 inches above grade on the near side. That coping will be about 16 inches wide, and will form a sort of bench seat most of the way around the pool. At the far end, the grade level will be raised to match the coping height, which because of the slope of the back yard will only be about six inches.

The blue stuff you are looking at is the 2 inch thick Dow Styrofoam Highload 40 insulation, most of which is glued (yes glued, with polyurethane foam) to the soil behind it. On the bottom of the pool, the insulation sits on 4 inches of crushed drain rock, which sits on a geotextile fabric membrane. The next thing to go into the pit is the plumbing and rebar grid, and after that we shoot gunite.

Heat losses for most pools are dominated by evaporation. We're going to be getting a safety cover, and one of the side effects of these covers is that they are close to vapor-tight. We'll keep it closed for most of the day and only open it to go swimming. As a result, I'm expecting evaporative losses to be quite small -- perhaps a half inch a month or so. On our 18x46 foot pool, that's 260 gallons/month. Multiply by 2270 kJ/kg (water's heat of vaporization), and that's 70,000 BTU/day. [Update: this evaporation estimate was dead on.]

Direct heat loss through the cover will be the largest remaining heat loss. The 24-hour average outside temperature in spring is around 60 degrees, and the safety cover will be something like R-1, so loss from a 85 degree pool would be 520,000 BTU/day. During the early spring and late fall, we'll probably lower this loss by putting a bubble-type cover over the safety cover. (I wasn't able to find an automatic safety cover which insulates.) The combination of the two covers will be around R-3, so losses will be around 180,000 BTU/day.

Most contractors tell me that the dirt under the pool is a fine insulator, but I think they really don't know what they're talking about. Houses use under-slab insulation to insulate their 70 degree interiors from the 55 degree earth heat sink. The pool will be at 85 degrees, which is twice that temperature gradient, so I think insulation will matter even more for the pool. In particular, I'm most concerned about the water table contacting the bottom of the pool in the spring and sucking all the pool's heat into an underground plume of warm water headed towards the San Francisco Bay. [Update: the water table never gets to the bottom of the pool, as our dirt is well drained.]

Let's suppose that concrete conducts 1.7 W/m-K. To convert that to more familiar units, 8 inches of concrete would be R-0.68 (which is terrible -- single-paned windows are better). I'll guess that the dirt, even when wet, insulates a bit as well, so that the bottom of the pool is about R-2. My pool will have an average depth of 7 feet (it has a 10.5 foot deep diving area), so it'll have an exposed area of about 1790 feet. If the pool temp is 85 degrees, and the ground temp is 60 degrees, that's 537,000 BTU/day, about three times my expected loss through the top in the spring. That's why I'm insulating the pool.

The blue Styrofoam has an R value of R-10. It is designed to deflect 5% at 40 psi, and is rated for continuous (dead) load of 13.3 psi. 10.5 feet of water plus 8 inches of concrete will be 5.25 psi, well within the dead load rating of the Styrofoam. The stuff should compress 0.33 mm when the pool is filled, which I don't think will cause cracking anywhere (thermal expansion is probably more than that).

The insulation changes the bottom of the pool from R-2 to R-12, so now I expect to lose 90,000 BTU/day, which is a savings of 447,000 BTU/day. To put that in perspective, on an average day my solar panels will deliver around 40,000 BTU each. I think I can squeeze 12 of them up onto the roof. The insulation is saving about as much heat flow as the panels put in!

To attach the insulation to bare dirt on the walls and shelves, I glued them on with Tap Plastics X-30 two-part expanding polyurethane foam, which I sprayed on with a pair of Wagner power sprayers. The trick here was to hold the panels firmly (with a few hundred pounds of force) against the dirt while the polyurethane expanded, which takes about 30 minutes. Once we did that the panels really stuck on well.

Note: I wore complete face covering, goggles, and breathed through an activated charcoal filter to take out the volatile organics. It was impossible to get the crew to wear the same protective gear. In the end, everything that was exposed got coated in a fine mist of polyurethane. The warning label says skin will develop an allergy to the stuff with repeated exposure. If you try this yourself, be careful, and be careful with your crew!

The soil at the bottom of the pool is firm clay, covered with filter fabric, covered with drain rock. Initially I tried gluing the insulation to the drain rock, but this doesn't work well. The insulation does not sit flat against the drain rock, and it rocks around a bit. Worse still, the polyurethane is quite springy, and was deflecting about a quarter inch under my body weight. This made me realize that the combinations of shelves, drain rock, and insulation is very bad, because the insulation on drain rock might settle, which would cause the pool to hang from the shelves, which would cause the gunite shell to crack. If I had it to do over again, I would eliminate the soil shelves, which are only there to reduce the cost of the gunite by $1500 or so.

Instead, I ripped up all the bottom insulation that the crews had installed and reinstalled it myself. I had already compacted the soil, first with the Bobcat, then with my feet (the crew were actually laughing at me), then with a heavy roller. Then I compacted the drain rock with the heavy roller. Then I cut the insulation into 15" x 24" squares and hand placed each one, tweaking the rock placement and vibrating the panel so that the rocks settled into a configuration which was flat for each panel. That took about four partial days, and only got finished because Martha got into the pit with me. I read later that a skilled laborer with one assistant is expected to place 100 square feet of under-slab insulation per hour, so I was about two times slower than that.

I'm still paranoid about settling, so I'm going to have the south and west walls of the pool done with #5 40 ksi vertical rebar on 6 inch centers. #5 is strong enough to actually support the entire pool weight (450,000 pounds filled) on the soil shelves, should the shelves not creep under that load. I also put a 1 foot chamfer on the edge of the shelf under the cover vault. The fillet of gunite that fills that chamfer, along with the rebar, will spread the torque from the pool wall hanging on that shelf.

[Update: I ended up with a mix of #3 40 ksi and #4 60 ksi rebar, with about half the strength necessary to hold up the whole pool. I figured I only had to hold up one end, and the rebar guy objected strongly to #5 -- he bent most of the rebar with his right knee!]

Another issue is the bond strength between the XPS insulation and the gunite. I've since built the pump vault, which is insulated as well, and the XPS/concrete bond there is perhaps only 1 to 3 pounds per square inch shear strength. If I assume 1 psi for the pool shell, then it will take about 140,000 pounds of shear, which is substantially less than the 450,000 pound filled weight of the pool. This shear strength is comparable to the shear strength of the polyurethane bond to the soil. This pool shell will be sitting on its bottom. The polyurethane is substantially more springy than the polystyrene, and I think it will deflect the 0.3mm in shear that will happen when we fill the pool.

I did not predict the cost well. I used 130 2 foot by 8 foot panels, with a small amount left over that I am using to insulate the pool piping. These cost $2800. I used 30 gallons of the X-30, which cost me about $1500. It took me and a crew of three guys four days to glue on the side panels, and I think that labor cost me $2500. The bottom I did myself, but the labor for that would probably have been another $1000 or so.

You can try to compare that cost to the cost of the panel array. The problem with the comparison is that the panels deliver the most heat when its warm, when you don't need it. The second problem is that the panel array is limited by the size of my roof, so I can't just spend an arbitrarily large sum on panels.

That said, standard FAFCO-type panels are something like $300 each, and produce 25,000 BTU/day. To generate the same amount of heat saved, you'd need 18 panels, which would cost $5400. However, the panels don't really work at all in November and April, when you need the heat most. The panels I'm using are SunEarth EP40s, which are glazed and insulated copper panels, and cost around $1100 each. These will deliver around 35,000 BTU/day, and will work in November and April. But I'd need 13 to match the insulation's savings. And that would cost $14,000! So I'm pretty confident the insulation will be a win.

I'm not quite done with the insulation. You can see a pile of pink insulation at the southeast corner of the pool. This is standard XPS, and it will be going around all the pool piping. I tried to find XPS pipe insulation, but the stuff is hideously expensive because it is all custom cut from large billets, usually for municipalities who are insulating their sewer pipes against frost. So instead I'm gluing together a little box of 2" XPS around all my pipe runs. Because the pool pump will be running 24 hours a day, the heat losses from the pipes can actually be comparable to the pool shell itself if not insulated. If you are building a pool, you might want to consider insulating your pipe runs even if you don't insulate the shell, because insulated pipe runs don't suffer any of the structural and installation issues that come with the shell.

Side note: I had a hell of a time finding a Highload 40 distributor. I ended up calling Dow directly, who referred me to White Cap Insulation in San Francisco, who sold me the stuff for $21.58 per 2" x 2' x 8' sheet. Note that standard 20 psi extruded polystyrene has a dead load rating of over 6 psi, so it would have been technically okay for my 5.25 psi of dead load. If I wanted to save around $600, I would probably have gone for the thinner stuff. It would also be easier to buy. I'm hoping that the extra-sturdy foam is buying me a little margin, which is nice to have because I don't have examples of other pools that have been built this way. [Update: somehow I miscalculated the amount of gunite in the pool, and it's a bit larger than my estimate here. So, I'm glad I have lots of extra margin on the load carrying capacity of the insulation.]

Side note two: the space down at the bottom of the deep end experiences really wild temperature swings right now. Because it is down low, it is radiatively coupled to the sky and not much else. When the sun is shining down there, it can get well over 100 degrees. As soon as the sun goes down, the temperature plummets, and because the pool is a depression, chilled air tends to stay down there.

Side note three: If you read this post and insulate your pool, or know of a pool that's been insulated, you might leave a comment so that there is some repository of success stories on the internet for this idea. And please please post if there has been a problem with an insulated pool.

Side note three: If you read this post and insulate your pool, or know of a pool that's been insulated, you might leave a comment so that there is some repository of success stories on the internet for this idea. And please please post if there has been a problem with an insulated pool.

Sunday, December 14, 2008

The World's Underwriter

This graph, from the New York Times, shows the extent of U.S. financial commitments made over the last year to deal with the credit crisis.

From December 2007 through September 2008, we committed $537 billion. That is not money spent, but it is money put at risk by guaranteeing various financial instruments, and by loaning to banks that could not otherwise get loans.

But in September 2008 the Fed went nuts, nearly doubling the commitment to $1097 billion, or around $5500 per taxpayer. (There are around 200M taxpayers, right?)

And then in October, the FDIC joined the Fed, and, according to the NYT, together they upped the commitment to $5069 billion. I am not following the NYT very well here, however, since it appears that $1600 billion of this refers to the size of the commercial paper pool, and not the size of the projected government purchases within that pool. So it's not like the government is actually selling $5 trillion of T bills.

It appears the Fed has become the world's underwriter. The commercial paper thing appears pretty transparent, for instance. The Fed sells T bills at 1% interest, and buys commercial paper at 5 to 10% interest. So long as the default rate is lower than the spread, the Fed makes money. Given the size of the money flow here, it is possible that the Fed could either make or lose amounts similar to the size of the national debt over the next couple of years.

Of course the problem is that someone at the Fed has to decide what rate they want for paper from which companies. Since the decisions required are vast -- they have to price the entire commercial paper market -- one presumes the same people are doing this that just presided over the credit default swap implosion. So, it seems like we might be more likely to headed for the "likely to double the national debt" outcome and less likely to end up at the "paid back the national debt" outcome.

This is Macroeconomics, for real. Wow. It really makes you wish there were a way to get off this train.

Friday, December 12, 2008

Prediction

That white paper got me thinking: what if the government made a bunch of other sensible decisions?

- They might shut down Yucca Mountain, and require that all nuclear waste be stored on the site of the reactor for 300 years. Nah, won't happen. [Update: They did it!]

- They might just have NASA cancel Ares-I and Ares-V, and leave it to SpaceX to provide a launcher. This might actually happen. All those folks in Florida and Utah that used to work for NASA contractors? Learn to build windmills. Some of you can learn to build Dragons and Falcons. [Update: Holy crap! They did it!]

- They might require all air conditioners and heat pumps to have short-term demand management controls. As the newer air conditioners got deployed, we'd have a lot less need for online throttled-down combustion gas turbines to back up all these new wind farms. I've not seen any rumblings of this yet.

- They might even standardize form factors for rechargable batteries... [Update: Um, they sort of did it! (Europe hsa standardized cellphone recharging plugs)]

Going Nuclear

Stephen Chu, the current director of the Lawrence Berkeley National Lab, and the guy that Obama just fingered to be the new Secretary of Energy, signed this paper in August of this year. The paper is a short, very high level, but clear and broad statement of why and how we should invest heavily in nuclear power. Usually, statements like this come from people with no clout.

Holy crap. This Barack Obama guy seems to be making at least some decisions I agree with. I'm confused and unused to this feeling, but I think I like it.

-Iain

Monday, December 01, 2008

Spend, spend, spending our way out of recession

We have a consensus among politicians in this country that we must spend our way out of this recession. Of course, there are many things to spend money on:

- For the last six years, the neocons within the Bush Administration have spent around 700 billion dollars of our money on wars, and committed another trillion or so to the aftermath of those wars (caring for the permanently maimed American soldiers).

- This March, the idea that everyone jumped at was spending money on consumer goods, so every American got a check for $400 from the government, and was exhorted to spend it on consumables. Pfft! Just like that, $80 billion gone.

- In just the last month, the Federal Reserve has spent hundreds of billions by buying stock in badly run banks whose value is justly plummeting as people realize how stupid their management was.

All of these have been colossal failures from an economic point of view. And I do mean colossal. The U.S. economy is about $13 trillion a year, and has a historic growth rate of about 3% per year. It is the most awesome generator of wealth ever. The economy usually generates about $400 billion a year in growth. And our government is now throwing away money at a rate which entirely negates the economy's ability to grow at all. The current trends guarantee that our children will be worse off than we are. We are within a single order of magnitude of blowing away the entire output of the U.S. economy, which would reduce us to hunter-gatherers amid fancy energy-starved infrastructure within a year or two. Lest you think that an order of magnitude increase in government spending is preposterous, consider that one department, the Fed, is now spending more than 1% of the U.S. GDP per month propping up just one industry. The auto industry is lining up at the trough, and others aren't far behind.

Although the things the government spends money on now are crippling the economy, this is actually a good time for government spending to grow, so long as we spend money on the right things. Private sector returns on investment are low, so the cost of borrowing has dropped, which means investments have longer to make a return. This is a great time for the government to spend money on things that will cause the economy to grow in the long term:

- Domestic power infrastructure, like wind farms and nuclear powerplants. These will make the cost of future energy more predictable. Predictability means less risk, so that the cost of capital for energy-intensive manufacturing, like fertilizers and aluminum and steel and plastic, will be lower in the U.S. than in other countries without the same infrastructure. That will give our descendants decades of competitive advantage, which is enough time for not just businesses but industries to grow.

- Health care efficiency. I'm not suggesting we spend more on health care itself -- we're spending too much on health care. I suspect that a huge amount of operational expense can be slashed from health care through radical restructuring without large amounts of investment. The restructuring will be radical though. Imagine the number of people put out of work if drug advertising stopped.

- Electrified transportation. Hydrocarbon-based transport will always rely on imported fuels subject to ever-more volatile price swings. The value of real estate depends in part on the cost of transportation (if you drive 40 miles to work at 20 mpg and $4/gallon and 3% discount, that's $100k present value), and so volatility in energy prices causes volatility in housing prices which caps the house value that people can afford. Worse still, we get situations like the current housing bubble, caused by just 2 million people simulaneously finding out they bought way too much house. (That's just 1.7% of the 116 million homes in the U.S.!)

Friday, October 31, 2008

Save GM's workers, but not GM

I've just listened to a discussion on KQED about whether the US government should bail out the auto industry. The reason the solution here is not obvious is that everybody assumes that to save the job of someone who works for GM, you have to save GM. I suspect that's not true.

Toyota makes lots of cars in the United States. I suspect the majority of Toyota's domestic sales are domestically built. It saves them shipping, and avoids exposure to foreign exchange risk. The overall point is that there is no problem with American workers making cars that sell. The problem is that some American workers are making the wrong cars, and that is the fault of their engineering and management.

The usual way for these things to work out is that GM would go bankrupt and it's assets would be sold. Toyota would hire some of those workers, and buy some of those assets on the cheap, because they'd know that with GM gone there would be a reduction in the supply of cars and so they could make more money by increasing their own production.

Crucially, the assets (e.g. assembly plants) would be sold for a fraction of their original cost because Toyota would have to adapt them to Toyota's production style. This is very important -- GM's production style isn't profitable, so those assets have to be changed to become profitable.

Also, crucially, the former GM workers hired by Toyota would have to be retrained. This takes a lot of time for Toyota. The rehiring process also tends to weed out at least some of the poorly producing workers.

All this adaptation of physical capital and retraining of workers is all good stuff. So what's so bad about bankrupcy?

GM's shareholders lose a lot of money. Actually, GM's shareholders lost a lot of money a long time ago. GM's total market cap isn't very large, and hasn't been for a long time, because GM has had bad management for a long time. I claim that this problem is not terrible and does not warrant intervention from the government.

GM's workers and suppliers have no business for a long time. This is the real problem, and this is something that the government can help with.

So, here is what I suggest. I suggest that because GM, Ford, and Chrysler are "too big to fail", the government should intervene before they shut their doors, and negotiate an orderly transfer of their assets to companies that can make those assets perform. I suggest that Toyota and Honda and Mercedes and so forth would be willing to purchase much of the assets of the big three for a fraction of their orginal price, and would be willing to take government inducements to keep the factories open and the workers employed while they are restructured and retrained.

The result will be that some assembly people will be put out of work, because not all the Big Three's plants will be purchased. The corporate management of the big three will go unemployed, which is fine, as they are responsible for the current distress in those companies. There will be differences between the financial commitments that GM has made to its workers, and those that Toyota makes its own, and the differences between those commitments will have to be worked into the sale price from GM to Toyota.

We need to clarify the idea of "too big to fail". Our commitment is to our people, not to our companies.

Toyota makes lots of cars in the United States. I suspect the majority of Toyota's domestic sales are domestically built. It saves them shipping, and avoids exposure to foreign exchange risk. The overall point is that there is no problem with American workers making cars that sell. The problem is that some American workers are making the wrong cars, and that is the fault of their engineering and management.

The usual way for these things to work out is that GM would go bankrupt and it's assets would be sold. Toyota would hire some of those workers, and buy some of those assets on the cheap, because they'd know that with GM gone there would be a reduction in the supply of cars and so they could make more money by increasing their own production.

Crucially, the assets (e.g. assembly plants) would be sold for a fraction of their original cost because Toyota would have to adapt them to Toyota's production style. This is very important -- GM's production style isn't profitable, so those assets have to be changed to become profitable.

Also, crucially, the former GM workers hired by Toyota would have to be retrained. This takes a lot of time for Toyota. The rehiring process also tends to weed out at least some of the poorly producing workers.

All this adaptation of physical capital and retraining of workers is all good stuff. So what's so bad about bankrupcy?

GM's shareholders lose a lot of money. Actually, GM's shareholders lost a lot of money a long time ago. GM's total market cap isn't very large, and hasn't been for a long time, because GM has had bad management for a long time. I claim that this problem is not terrible and does not warrant intervention from the government.

GM's workers and suppliers have no business for a long time. This is the real problem, and this is something that the government can help with.

So, here is what I suggest. I suggest that because GM, Ford, and Chrysler are "too big to fail", the government should intervene before they shut their doors, and negotiate an orderly transfer of their assets to companies that can make those assets perform. I suggest that Toyota and Honda and Mercedes and so forth would be willing to purchase much of the assets of the big three for a fraction of their orginal price, and would be willing to take government inducements to keep the factories open and the workers employed while they are restructured and retrained.

The result will be that some assembly people will be put out of work, because not all the Big Three's plants will be purchased. The corporate management of the big three will go unemployed, which is fine, as they are responsible for the current distress in those companies. There will be differences between the financial commitments that GM has made to its workers, and those that Toyota makes its own, and the differences between those commitments will have to be worked into the sale price from GM to Toyota.

We need to clarify the idea of "too big to fail". Our commitment is to our people, not to our companies.

Subscribe to:

Posts (Atom)

.jpg)

.jpg)

.jpg)