As a side effect, everyone involved with the testing is now soaking wet. Much of the piping is not actually solvent-welded together right now, so there were the occasional blowouts. Fortunately, we have a blue sky and 75 degree air outside right now, so wet is just fine. If we had a pool, we'd be swimming (ahem).

Here are two unit fountains running at about 60% of design flow. Note the smooth flow. It's splashing a bit when it hits the tub, but that'll go away when it's got more than a half-inch of water to fall into.

Details:

- The streams do not quite reach the same height. I'm pretty sure this has to do with a small difference in their pointing angle, so I'm pretty sure they'll all line up when properly installed dead vertical.

- When supplying the fountains with water from the hose, pressure variations from the street supply were making their way to the fountain. These were probably low-frequency variations, maybe 1 to 3 hertz.

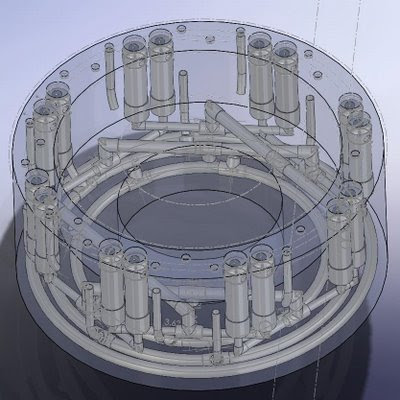

- I considered a surge tank, but the volume required was too large (over 20 gallons). Instead, I have a simple open-topped vertical pipe teed into the line from the pump to the fountain. The pipe only needs to be a few inches taller than the height of the fountain jets. The production system will have perhaps an extra foot or two. You can see the pipe in the foreground.

- I tried placing the tee close to the unit fountain, and that worked well, and then I tried placing it next to the pump, and that worked about as well. This result indicates the flow instability comes from the pump and street supply, and not from turbulence within the fountain itself. (Whew!)

- The nozzle is a nonlinear resistor, so it was moving the energy from low frequency variations to higher frequency harmonics.

- The nozzle is nonlinear because it converts pressure into velocity head with almost perfect efficiency. If you double the pressure, you double the velocity head -- the height to which the water will jump. I confirmed this by varying the flow through the system and noting that the water always jumped to a few inches lower than the water level in the vertical pipe capacitor. A doubling of velocity head means an increase by sqrt(2) of velocity, and flow is (sort-of) proportional to velocity. As a result, flow increases with the square root of pressure.

- The nozzle diameter is 0.500 inches, but the flow diameter appears to be 0.410 inches. I didn't expect this. The reason is that the flow at the knife edge is horizontal, and it turns through a radius of 0.045 inches. I suspect that at the higher flow velocity in the production system, the stream diameter will actually decrease.

- As a result of the small stream diameter, I'm going to have to throttle back the pumps. The fountain was designed to throw 193 gallons per minute 59 inches horizontally with 16 0.500" diameter streams. Now that the streams are smaller, I'll have to throttle back to 130 gallons per minute, or lower. I'm not too happy about that.

- The stream is even more wickedly nonlinear than the nozzle. The principle problem is that slightly faster flow has over a second to catch up to slightly slower flow. The stream goes at about 140 inches/second at the nozzle. So a 1% variation in flow yields a longitudinal variation of over 2 inches by the time impact happens. If that happens in less than 10 inches (more than 14 hertz), you get blobs large enough to cause the stream to turn into drops.